PRODUCTS

Contact us

86 17344894490Mobile:86 17344894490

Email:info@signialuminium.com

Skype:signialuminio

Sales Office:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan,China

Factory Address:Industrial District, Xin'an, Luoyang city, Henan Province,China

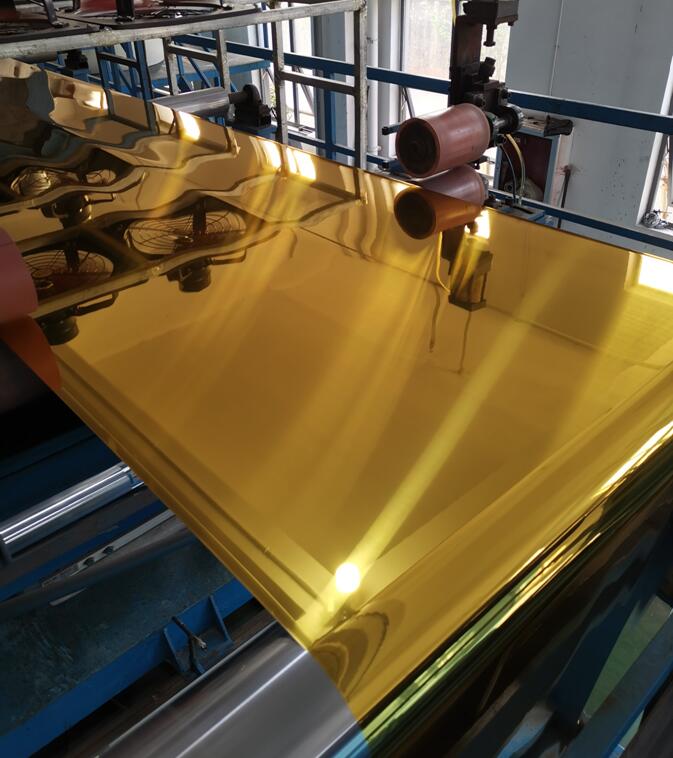

how to polish aluminum sheet to mirror finish

how to polish aluminum sheet to mirror finish

Mirror aluminum plate requires the surface to be as bright as a mirror, and the plate shape is as flat as glass. Mirror aluminum plates have been widely used in aerospace, mold processing and civil industries abroad. In China, mirrored aluminum plates are also urgently needed aviation materials in the aviation field, such as fighters and new military fighters. In terms of building decoration materials, the production templates of the film used for pasting furniture, floors, walls, ceilings, etc. all require mirrored aluminum plates; in addition, now mobile phones, cameras Mirror surface aluminum plates are also used in molding molds for plastic optical components used in other industries.

1. Mechanical polishing

Mechanical polishing refers to the grinding process between the high-speed rotating polishing wheel coated with polishing paste and the part grindstone, which has improved the surface gloss of metal products. It is generally obtained by manual polishing with a polishing wheel, which has high labor intensity and low polishing efficiency, and the obtained mirror aluminum plate has poor surface flatness and uniformity. In addition, the metal dust produced by the polishing is relatively harmful to the health of the operators. The current aluminum plate polishing machine adopts single-wheel polishing, and the surface roughness of the obtained mirror aluminum plate is relatively large, and there are scratches or lines on the surface, which cannot meet the higher requirements of use, and requires multiple polishing to meet the requirements. Now there is a need for a mirror aluminum plate polishing device with higher polishing efficiency, better polishing uniformity, better flatness and smoother surface.

2. Chemical polishing

Chemical polishing is one of the most common polishing processes in industrial applications. The chemical polishing equipment is simple, saving power, high efficiency, low cost, eliminating the cumbersome steps of mounting, and is not limited by the shape and size of the parts, especially when the parts with small dimensions and complex shapes cannot be mechanically polished, chemical polishing A uniform and bright surface can be obtained, fully demonstrating the superiority of chemical polishing.

3. Electrolytic polishing

In the polishing process, electrolytic polishing has the best quality, and electrolytic polishing has always occupied a very important position in surface finishing.

| Specification ( polish aluminum mirror finish sheet) | |||||

| Alloy | Temper | Thickness(mm) | Width(mm) | Length(mm) | |

| 1050, 1060, 1070 | O, H14, H16 | 0.15~3.0 | 50~1500 | >=1000 | |

| Tensile strength | Yield strength | Elongation | Total reflectivity | Diffuse reflectivity | |

| 140N/mm2 | 125N/mm2 | ≥2% | 80%~86% | ≤12% | |

|

Application: 1. Household appliances and furniture, such as door mirror, wall mirror, dressing mirror. 2. Architecture, such as windows or interior decoration of buildings (store, gymnasium, bathroom, washroom, etc). 3. Traffic vehicles, such as the windows of train, bus, car, etc. |

|||||