PRODUCTS

Contact us

86 17344894490Mobile:86 17344894490

Email:info@signialuminium.com

Skype:signialuminio

Sales Office:A126 Building 4, No.89 Science Avenue,National HI-Tech Industry Development Zone,Zhengzhou,Henan,China

Factory Address:Industrial District, Xin'an, Luoyang city, Henan Province,China

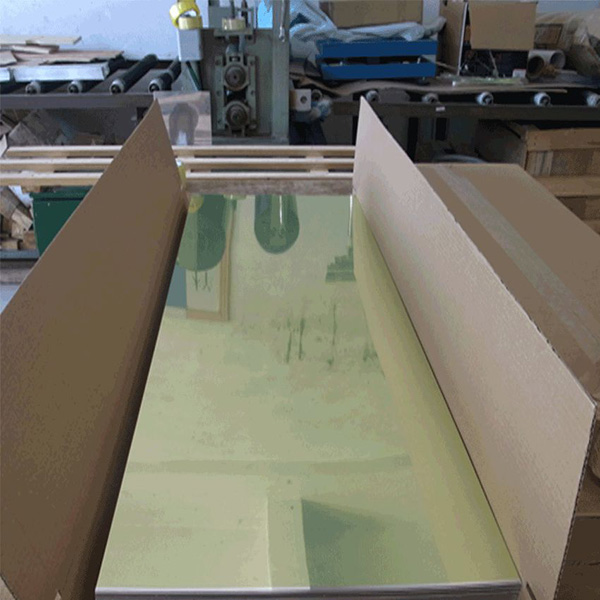

Electro-polishing mirror aluminum

Electro-polishing mirror aluminum

Electro-polishing mirror aluminum

The purity of aluminum can affect the polishing quality, compared with commercial aluminum, 5N5 high purity aluminum has better surface quality after polishing. for 5N5 high purity aluminum, the reflectivity of polishing mirror aluminum can reach 98% and the surface cleanliness can be Grade I, in two solutions, and for 1085 commercial pure aluminum the reflectivity can reach 90% and the surface cleanliness is Grade I in the HCIO4 solution. But the reflectivity can only reach 85% in H2SO4-H3PO4 solution can reach 90%, but the surface cleanliness is Grade II,

The optimal electro-polishing aluminum showed that for 1085 commercial pure aluminum in HCLO4 solution, current density is 0.1-0.2A/cm², polishing time is 10-12min, polishing temperature is 5-15 ℃.

5N5 high purity aluminum in HClO1 solution, current density is 0.2 A/cm², polishing time is 22-28min, polishing temperature is 5-10℃, and for 5N5 high purity aluminum in H2SO4 solution, current density is 0.2-0.4A/cm², polishing time is 15-35min, polishing temperature is 85-95℃.

During the process of electro-polishing, the polishing mirror aluminum will have some defects, such as white coating, pits sand, surface flow marks can appear under unsuitable conditions of polishing technology, which can result in worse reflectivity and surface cleanliness.